Strainers, Flanges & Venturi Products

Strainers

• Specification: IPS-G-PI-230

• Type: T-Type, Y-Type, Duplex, Compact Duplex

• Nominal Sizes: 2"~42"

• Rating: CL150~CL2500

• Material: Carbon Steel & Stainless Steel

• NACE MR0175/ISO 15156 compliance

Venturi Flow Element

• Specification: ISO 5167

• Nominal Sizes: 2" - 56"

• Rating: CL150-CL 2500

• Overlay: lnconel, Stellite

• Suitable for Sour Service,

• NACE MR0175/ISO 15156 compliance

Barred Tee

• Specification: ASME B16.9, MSS SP 75,

IPS-D-PI-149

• Nominal sizes: 1/2" ~ 56"

• Material: A860 WPHY, A234 WPB, Bar materials hot rolled mild steel plate compatible with tee body material unless otherwise specified.

• Suitable for Sour Service

• NACE MR0175/ISO 15156 compliance

Anchor Flange

Anchor flanges are forged fittings installed on pipelines and embedded in reinforced concrete blocks. They are used to restrain or limit main line thermal expansion or contraction and transfer built-up stresses to external structures or larger foundation.

• Specification: ASME B16.5, ASME B16.25, ASME SECTION VIII

• Size Chart: Normal Pipe Size 2" to NPS 56"

• Rating: Class 150 to Class 2500

• Materials: Carbon Steel & Stainless Steel

• NACE MR0175/ISO 15156 compliance

Choke

Flange

• Specification: API 6A

• Nominal sizes: 2 1/16" up to 11"

• Rating (API 6A): 3000, 5000, 10000, 15000

• Pressure Drop: According to request

• Material: 45K, 60K, 75K

• Suitable for Sour Service

• NACE MR0175/ISO 15156 compliance

Spectacle Flange

• Specification: ASME B16.48, ASME B16.5

• Type: Figure-8 Blank, Paddle Blank, Paddle Spacer, Application: Water Pipeline Industry, Nuclear Power Plant, Natural Gas Industry, Fabrication Industry, Oil And Gas Industry, Chemical Industry

• Rating: #150, #300, #600, #900, #1500, #2500

• Sizes: 1/2" ~ 24"

• NACE MR0175/ISO 15156 compliance

Orifice Flange

Specification: ASME B16.36, ASME B16.5

Rating: #300, #600, #900, #1500, #2500

Sizes: 1/2" ~ 24"

Material: Carbon Steel & Stainless Steel

NACE MR0175/ISO 15156 compliance

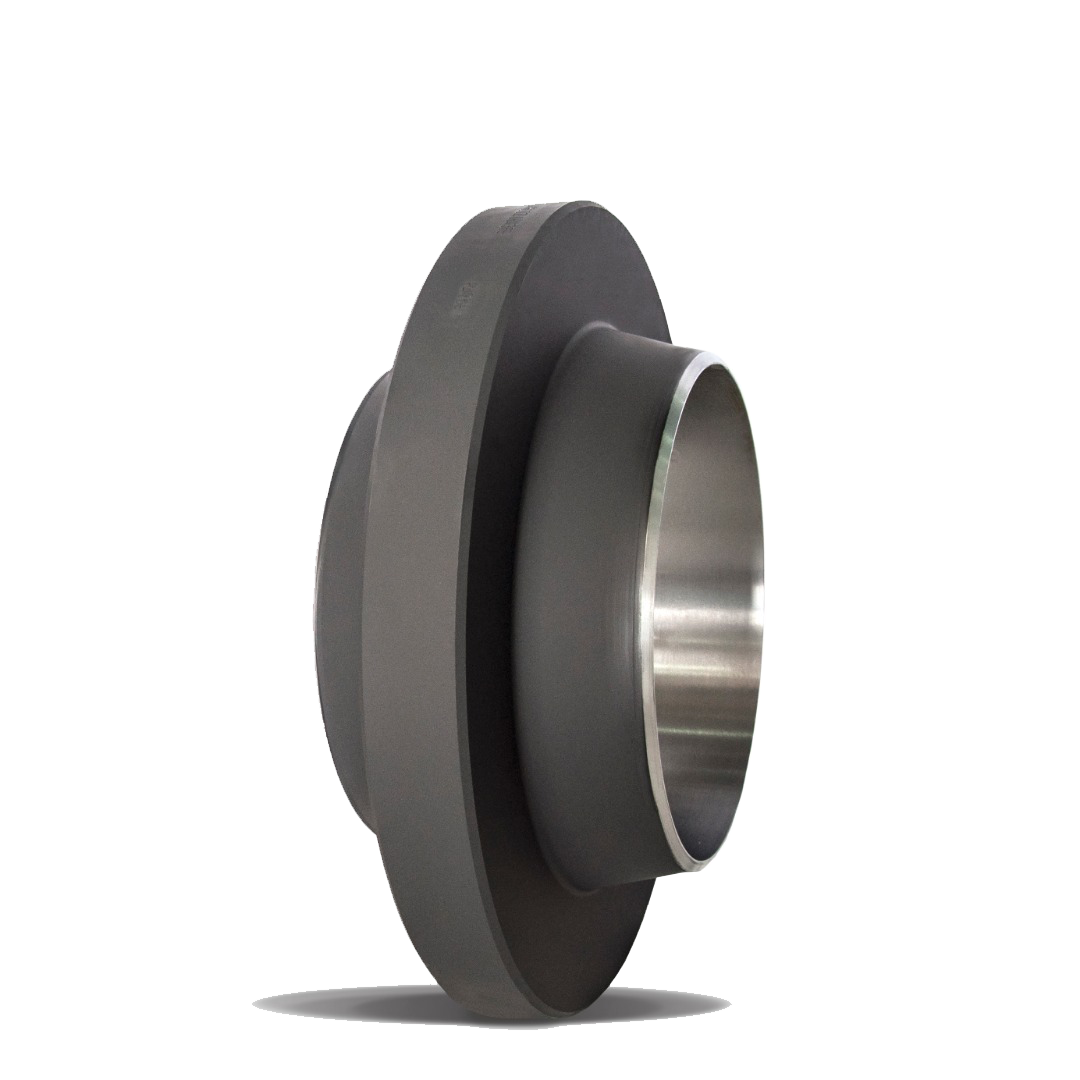

Insulating Joint

Key Features:

• Electrical Isolation: Prevents current flow between pipeline sections.

• High Dielectric Strength: Typically > 5 kV.

• Resistance: Insulation resistance ≥ 10⁶ Ohms.

• Pressure Rating: Available from ANSI Class 150 to 900 (and higher upon request).

• Temperature Range: -30°C to +120°C or as per design.

• Corrosion Protection: Epoxy-coated or stainless steel options available.

• Seal Integrity: O-ring and gasket seals prevent leakage and contamination.

• Welded Construction: Ensures permanent mechanical strength and leak-proof operation.

Standards Compliance:

• API 5L / ASME B31.3 / ISO 15590-1

• NACE MR0175 (for sour service)