Actuator Products

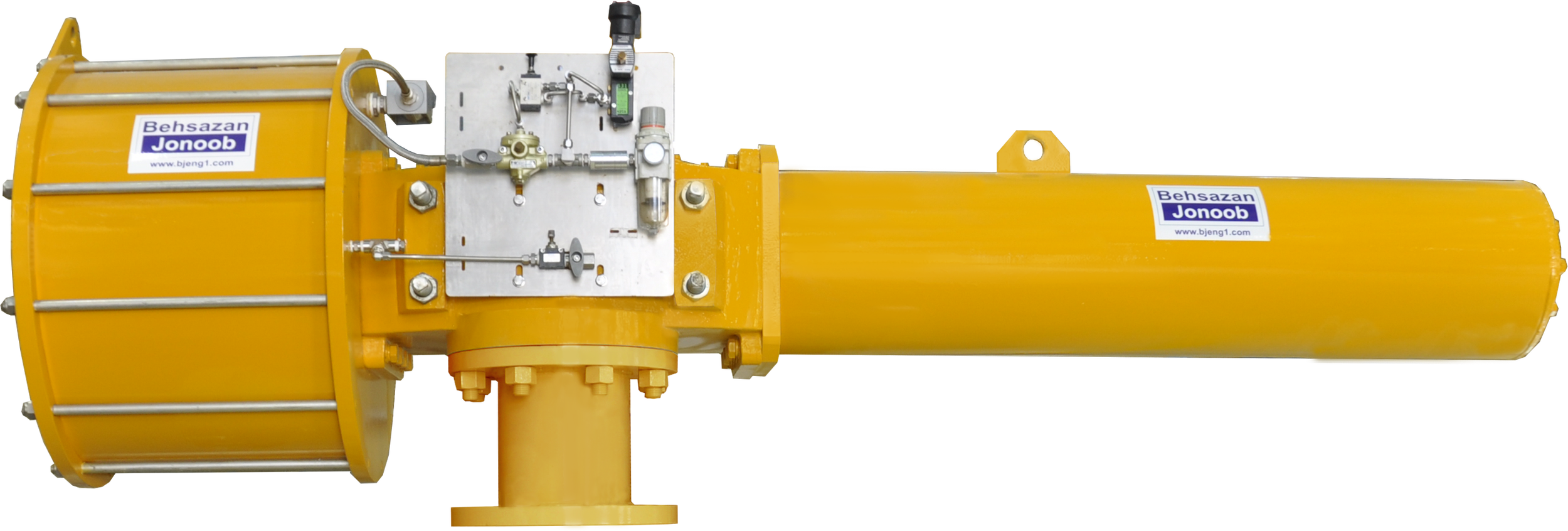

Pneumatic Scotch Yoke Actuator

BJ Pneumatic actuators are designed for on-off or modulating control of quarter turn ball, butterfly, plug or damper style valves.

Suitability for SIL 2 & SIL3 environments

Solenoid Valve Testing

Fire Proofing

Instrument Air Supply Pressure Working (Barg): 4.0 ~ 7.0

Hydraulic Actuator

Actuator type: Hydraulic and Pneumatic single acting spring return,

Double acting, Gas Over OilSize and Rating: Suitable for valves up to 56in and up to CL4500

Features: Scotch and Yoke , Rack and Pinion

Actuator torque output: Up to 150,000 Nm

Specification: ASME VIII div.1 and EN13445

Application: ON/OFF, ESD, LBV, HIPPS

Pneumatic Linear Actuator

Spring-Return Pneumatic Linear Actuators, are suitable for the operation of linear valves for ON-OFF and modulating heavy-duty service.

Complete control panel

Emergency tank

Manual hand pump

Partial Stroke Test (PST) device

Electro-Hydraulic Scotch Yoke Actuator

It is powered by a motor which converts electrical energy into mechanical torque.

Suitability for SIL 2 & SIL3 environments

Partial Stroke Test (PST) device

Self contained, only requires electrical power

Fail-safe close, open

Pneumatic Rack & Pinion Actuator

Rack and Pinion actuators are for automation and operation of quarter-turn valves.

The actuators are available in two constructions: Spring Return and Double Acting. Mechanical Spring Return is for fail-safe applications and can be assembled for “Fail-Close” or “Fail-Open” safety function.

Double Acting actuators can be used for a “Fail-In-Last-Position” safety function.

Special teeth profile double rack and pinion construction

Maximum working pressure 8 bar, Special version for 13 bar available

Temperature rang NBR -20 °C to +80 °C, VITON -20 °C to +125 °C,

Flourosilicon -60 °C to +110 °C

Robust anodized aluminum bodies ensure even expansion under thermal influences, no jumping of the piston and a high level of corrosion protection.

Compliance with international interface standards ISO 5211/DIN 3337 and VDE/VDI 3845 (NAMUR).

Simple retrofitting of accessories, such as solenoid valves, limit switch, positioners, etc.

Piston guide bearing with wide contact surface, increased efficiency and cycle life.

Independent open and closed adjustment (standard across S050-S200) is indispensable where finite adjustment or limited rotation is required.

Valve and accessory connections according to the latest international standards.

Stainless steel pinion.

Body with dual ISO 5211 mounting connections.

MaxGuardTM – Special coating for corrosive and aggressive applications.

Gas Over Oil Actuator

The Gas Over Oil Actuator can be used for on/off applications. It is available in a double acting version and delivers torque up to 200.000 Nm

SCOTCH YOKE Mechanism

Double Acting

Symmetric or canted yoke design

160 BARG Max power supply

Output Torque Up to 800.000 Nm

Standard temperature rang -30ºC +30ºC

Low temperature version -60ºC +85ºC

PED 97/23/EC Compliant

ATEX 94/9/EC Compliant

IP 66, 67, 67M, NEMA 4, 4X, 6

Corrosion resistant Cylinder

Protected travel stops are standard

Sweet Gas - Sour Gas Supply (H2S<=6% / CO2<=10%)

Actuator in carbon steel - NO Aluminium NO Cast Iron

Hydraulic or Pneumatic Torque limiting device

Local - Remote Control Group

High pressure Pneumatic Limit Pilot switch

Line break device with both gas or electronic version available

ESD - opening prevention - Manual reset